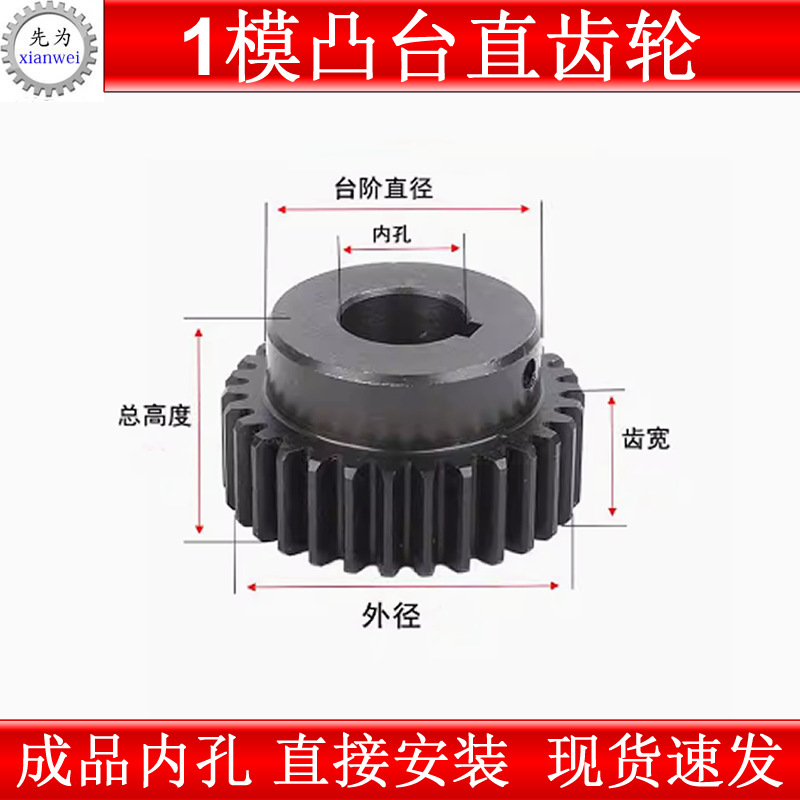

Introducing the Spur gear 1 mold 36 teeth -45 teeth blackening motor metal finished product hole boss gear, a premium component for your mechanical projects. These gears are designed for precision and durability, featuring blackening treatment for enhanced resistance against wear and corrosion. Ideal for use in motors and linear guide accessories, they offer reliable performance and long-lasting quality.

Enhance your mechanical systems with the Spur gear 1 mold 36 teeth -45 teeth blackening motor metal finished product hole boss gear. These gears are crafted for superior performance, with blackening treatment that ensures durability and longevity. Perfect for motors and linear guide accessories, they provide precise and efficient operation. Choose these high-quality gears for your next project and experience the difference in performance and reliability.

Enhance your industrial machinery with high-quality helical gear grinding services! Our helical gear processing uses 45 steel, ensuring durability and precision. Whether you need a single gear or a complete set, our expert team can deliver the perfect solution for your needs.

Our helical gear grinding services are designed to meet the highest standards of quality and performance. With years of experience and advanced machinery, we guarantee precise and reliable gears that will enhance the efficiency and longevity of your industrial equipment. Trust us to deliver the best in helical gear processing.

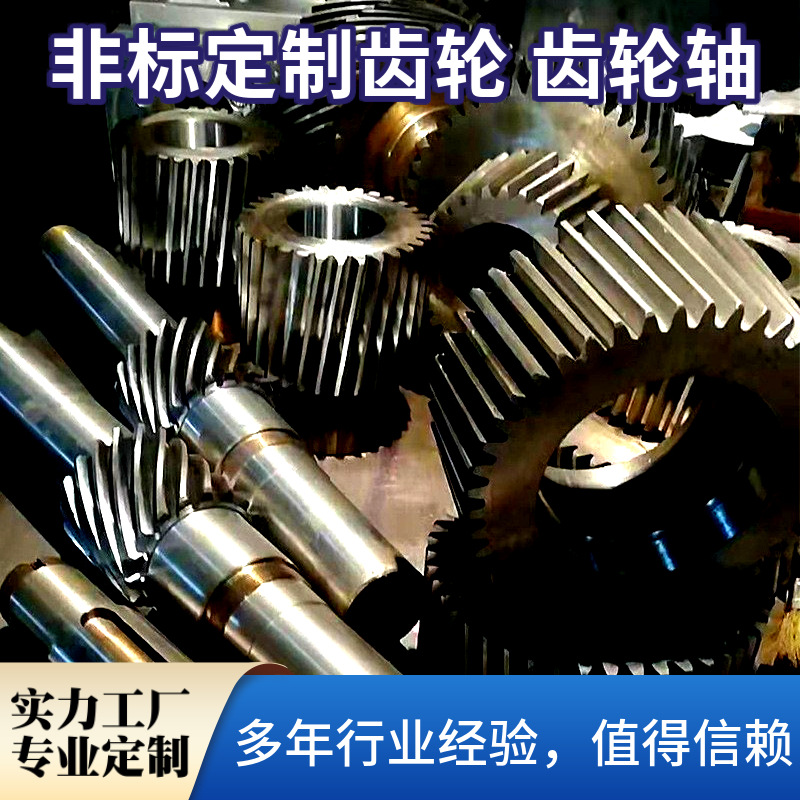

Customize your industrial machinery with precision-engineered gear shafts. Our non-standard gear shaft processing service ensures that your large industrial machinery operates smoothly and efficiently. Whether you need a transmission gear tailored to your specific requirements or a 45# steel gear produced to exact specifications, our expert team is here to deliver. Trust us to map out and manufacture the perfect gear for your application.

Elevate your machinery's performance with our bespoke gear shaft solutions. Designed for durability and reliability, our custom gear shafts are crafted to meet the unique demands of your industrial equipment. From initial design to final production, we prioritize quality and precision, ensuring that every gear we produce enhances your machinery's functionality. Choose us for gear customization that stands the test of time.

Introducing our High Temperature Resistant Special-Shaped Gear Laser Cutting Machine—a game-changer in precision engineering. Designed for durability and efficiency, this machine tool ensures high-quality, duplex gear production with unmatched accuracy. Whether you're in the powder metallurgy industry or need specialized gear solutions, our factory direct sales offer unbeatable value and performance.

Elevate your manufacturing process with our state-of-the-art laser cutting technology. This machine not only withstands extreme temperatures but also delivers intricate, special-shaped gears with precision. Ideal for high-demand applications, it’s a must-have for any factory looking to enhance productivity and quality. Invest in innovation today!